Corrosion Protection

Corrosion causes annual costs of about 2500 billions, most of which is spent on corrosion protection. Organic coatings based on thermosetting resins are most often used as corrosion protection. However, these resins are susceptible to localized defects and thus to localized corrosion, and they cannot be recycled.

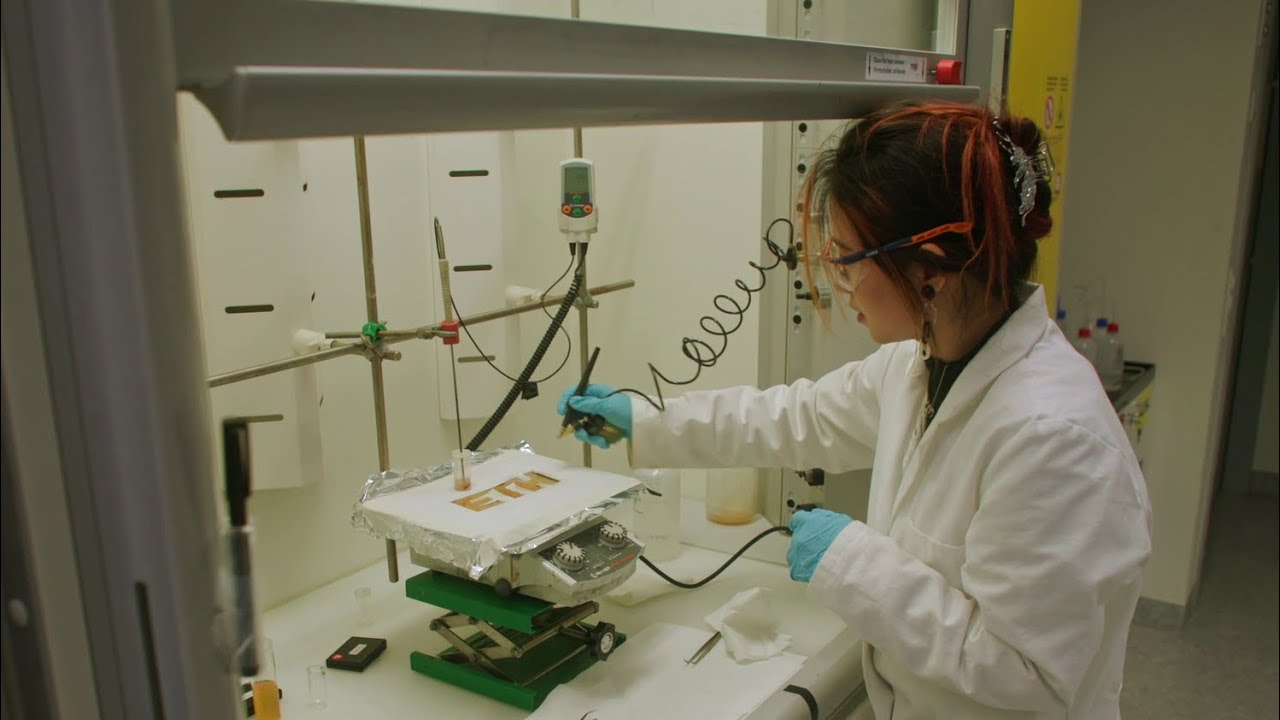

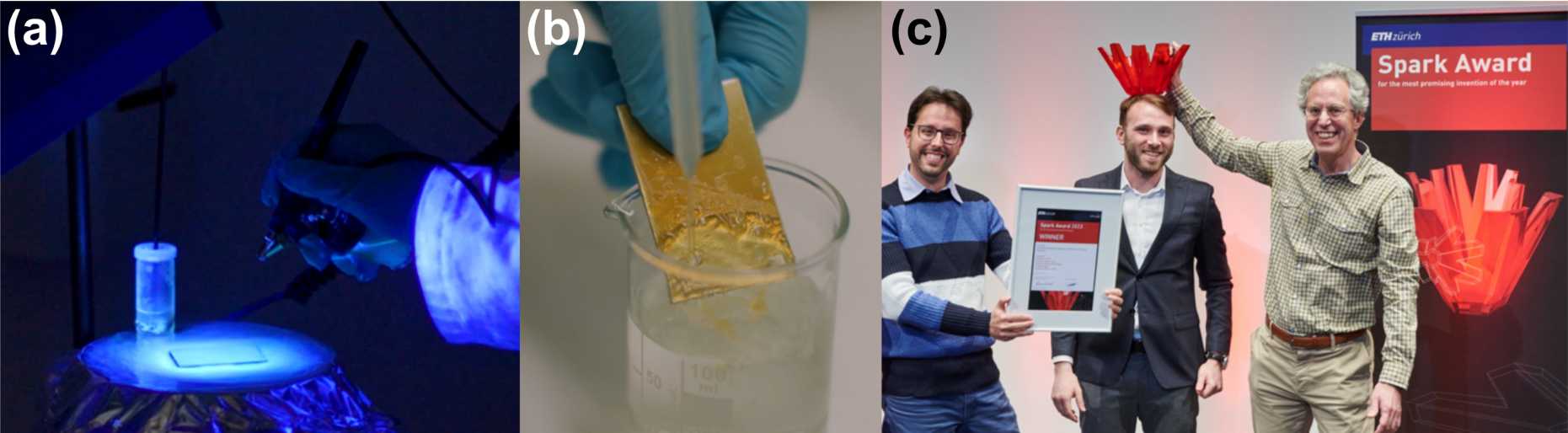

The Multifunctional Materials Laboratory has been working on the synthesis and characterization of poly(phenylene methylene) (PPM) for several years. PPM is a poorly studied polymer with unusual optical properties. It is luminescent, although it is not π-conjugated. We optimized the synthesis of PPM in terms of its molecular weight and also adjusted its composition by side-chain engineering to improve its processability. It turned out that PPM-based copolymers have excellent corrosion protection and self-healing properties and can be processed into high-quality coatings on many different metal substrates using standard techniques. Most importantly, PPM-based coatings can be separated from metal substrates using conventional solvents, allowing both the coating and the metal to be recycled.

Our work on PPM-based coatings for corrosion protection was recognized with ETH Zurich's Spark Award 2023 for the "most promising invention leading to a patent application."

For more information about PPM-based coatings watch the movie below: